|

|

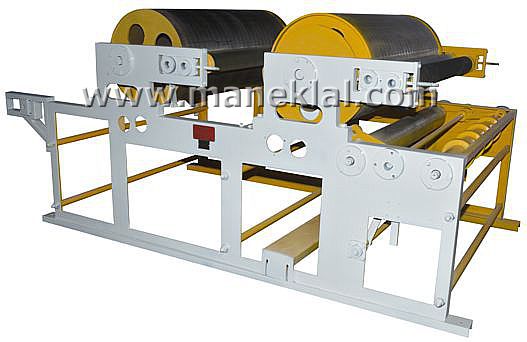

| Paper Corrugation Machines - High Speed, Single Face, Oblique Type |

|

|

|

Features: |

|

|

| Model: | PCM-45 | PCM-48 | PCM-52 | PCM-62 | PCM-64 | PCM-72 | PCM-80 |

| Machine Size: | 45" / 1125 mm | 48" / 1200 mm | 52" / 1300 mm | 62" / 1575 mm | 64" / 1625 mm | 72" / 1825 mm | 80" / 2025 mm |

| Roll Diameter: | 10" / 250 mm | 10" / 250 mm | 10" / 250 mm | 10" / 250 mm | 10" / 250 mm | 10" / 250 mm | 10" / 250 mm |

| Production Speed: | 35 m/min | 35 m/min | 35 m/min | 35 m/min | 35 m/min | 35 m/min | 35 m/min |

| Motor: | 5 HP | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 15 HP | 15 HP |

| Approx. Heating Load: | 21 kW | 25 kW | 30 kW | 36 kW | 42 kW | 48 kW | 48 kW |

| Approx. Net Weight: | 3500 kg. | 4000 kg. | 4500 kg. | 5000 kg. | 5500 kg. | 7500 kg. | 8000 kg. |

| Shipping Volume: | 9 m3 | 10 m3 | 11 m3 | 13 m3 | 14 m3 | 16 m3 | 18 m3 |

Motorized Self Loading Reel Stand |

Standard Accessories: One set of Rolls to make standard flutes

(A, B or C), heater, motorized self loading reel stand, sheet

impulse counter and electricals |

|

|

| Auto Rotary Sheet Cutting Machines / Reel-to-Sheet Cutters |

|

|

|

Features: |

|

|

| Model: | RSC-54 | RSC-64 | RSC-69 | RSC-74 |

| Machine Size: | 54 / 137 cm | 64 / 162 cm | 69 / 175 cm | 74 / 188 cm |

| Minimum Length Cut: | 16 (405 mm) | 16 (405 mm) | 16 (405 mm) | 16 (405 mm) |

| Motor: | 2 HP | 2 HP | 2 HP | 3 HP |

| Approx. Net Weight: | 1200 kg. | 1400 kg. | 1600 kg. | 1800 kg. |

| Shipping Volume: | 4 m3 | 4.5 m3 | 5 m3 | 5.5 m3 |

|

|

|

|

| Eccentric Slotting Machines |

|

Purpose: |

|

Specifications: |

| Model: | ES-65 | ES-75 | ES-85 | ES-95 | ES-105 |

| Machine Size: | 65 / 165 cm | 75" / 190 cm | 85 / 215 cm | 95 / 241 cm | 105 / 266 cm |

| Minimum Distance between Slots: | 14" | 17" | 18" | 18" | 18" |

| Width of Corner: | 3.5" | 3.5" | 3.5" | 3.5" | 3.5" |

| Motor: | 2 HP | 3 HP | 3 HP | 5 HP | 5 HP |

| Approx. Net / Gross Weight: | 1200 / 1500 kg. | 1400 / 1750 kg. | 1600 / 2100 kg. | 1800 / 2300 kg. | 2000 / 2500 kg. |

| Shipping Volume: | 5.5 m3 | 6 m3 | 6.5 m3 | 7 m3 | 8 m3 |

|

|

| Four Bar Rotary Cutting and Creasing Machines |

|

Purpose: |

|

|

| Model: | RCC-65 | RCC-75 | RCC-85 | RCC-95 | RCC-105 | RCC-120 |

| Machine Size: | 65 / 165 cm | 75" / 190 cm | 85" / 216 cm | 95 / 241 cm | 105 / 266 cm | 120 / 305 cm |

| Speed: | 3 rpm | 3 rpm | 3 rpm | 3 rpm | 3 rpm | 3 rpm |

| Motor: | 1.5 HP | 2 HP | 2 HP | 3 HP | 3 HP | 5 HP |

| Approx. Net / Gross Weight: | 1100 / 1500 kg. | 1300 / 1800 kg. | 1500 / 2000 kg. | 1700 / 2200 kg. | 1900 / 2400 kg. | 2100 / 2600 kg. |

| Shipping Volume: | 4 m3 | 5 m3 | 6 m3 | 7 m3 | 8 m3 | 9 m3 |

Standard Accessories: |

|

| Sheet Pasting Machines |

|

Purpose: |

|

|

| Model: | SPM-45 | SPM-55 | SPM-65 | SPM-72 | SPM-85 |

| Machine Size: | 45 / 114 cm | 55 / 140 cm | 65 / 165 cm | 72 / 183 cm | 85 / 216 cm |

| Motor: | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP |

| Approx. Net / Gross Weight: | 400 / 450 kg. | 450 / 500 kg. | 500 / 550 kg. | 600 / 700 kg. | 700 / 800 kg. |

| Shipping Volume: | 2.0 m3 | 2.3 m3 | 2.5 m3 | 2.8 m3 | 3.6 m3 |

|

Standard Accessories: Motor, Pulley and V Belts |

|

| Paper / Board Cutting Machines - hand operated |

|

|

Specifications: |

| Model: | BC-52 | BC-65 |

| Machine Size: | 52" x 62" / 132 x 157 cm | 65" x 70" / 165 x 178 cm |

| Front Working: | 18" / 457 cm | 18" / 457 cm |

| Approx. Net / Gross Weight: | 600 / 700 kg. | 700 / 800 kg. |

| Shipping Volume: | 4 m3 | 5 m3 |

|

Standard Accessories: Front and Back Guides |

| Sheet Pressing Machines |

|

Purpose: |

|

|

| Model: | SP-75 | SP-85 | SP-105 |

| Machine Size: | 65" x 75" / 165 x 190 cm | 65" x 85" / 165 x 216 cm | 65" x 105" / 165 x 266 cm |

| Motor: | 0.5 HP | 0.5 HP | 0.5 HP |

| Approx. Net / Gross Weight: | 450 / 750 kg. | 500 / 800 kg. | 600 / 900 kg. |

| Shipping Volume: | 3.0 m3 | 3.5 m3 | 4.0 m3 |

|

Standard Accessories: Motor, Pulley and 'V' Belts |

| Flexo Printing Machines |

Model: FPM-72 Two Colour Flexo Printing Machine |

Purpose: |

|

|

| Model: | FPS-60 | FPS-72 | FPS-90 | FPM-60 | FPM-72 | FPM-90 |

| Machine Size: | 50 x 60 / 127 x 152 cm | 52 x 72 / 132 x 183 cm | 60 x 90 / 152 x 228 cm | 50 x 60 / 127 x 152 cm | 52 x 72 / 132 x 183 cm | 60 x 90 / 152 x 228 cm |

| Colours: | Single Colour | Single Colour | Single Colour | Two Colours | Two Colours | Two Colours |

| Motor: | 0.5 HP | 0.5 HP | 0.5 HP | 2.0 HP | 2.0 HP | 2.0 HP |

| Approx. Net / Gross Weight: | 1000 / 1300 kg. | 1200 / 1500 kg. | 1700 / 2200 kg. | 1500 / 2000 kg. | 1800 / 2400 kg. | 2400 / 3000 kg. |

| Shipping Volume: | 8 m3 | 9 m3 | 10 m3 | 10 m3 | 11 m3 | 15 m3 |

Standard Accessories: Motor, AC Drive for Variable Speed, Anilox Roller and Rubber Roll for Printing, Endless Blanket, Digital Counter with paper sensor |

|

|

| Heavy Duty Platen Punching, Creasing, Cutting, Embossing Machines |

|

|

|

Features: |

|

|

| Model: | PPP-1 | PPP-2 | PPP-3 | PPP-4 | PPP-5 | PPP-6 | PPP-7 |

| Inside Chase: | 20 x 26 / 50 x 66 cm | 20 x 30 / 50 x 76 cm | 25 x 37 / 63 x 94 cm | 32 x 42 / 81 x 106 cm | 36 x 50 / 91 x 127 cm | 42 x 62 / 106 x 157 cm | 56 x 76 / 142 x 193 cm |

| Platen Size: | 23 x 29 / 58 x 73 cm | 23 x 33 / 58 x 83 cm | 28 x 40 / 71 x 101 cm | 35 x 45 / 89 x 114 cm | 39 x 53 / 99 x 134 cm | 45 x 65 / 114 x 165 cm | 59 x 79 / 150 x 200 cm |

| Impressions per Hour: | 2000 | 2000 | 1800 | 1500 | 1200 | 700 | 600 |

| Motor: | 3 HP | 3 HP | 5 HP | 7.5 HP | 7.5 HP | 15 HP | 15 HP |

| Approx. Net / Gross Weight: | 2500 / 2800 kg. | 3000 / 3400 kg. | 4000 / 4500 kg. | 5000 / 5500 kg. | 6500 / 7000 kg. | 9500 / 10200 kg. | 10200 /11000 kg. |

| Approx Dimensions: | 1.3 x 1.8 x 1.5 m | 1.4 x 2.0 x 1.5 m | 1.6 x 2.2 x 1.6 m | 1.9 x 2.3 x 1.6 m | 2.1 x 2.5 x 1.7 m | 2.5 x 2.8 x 1.7 m | 2.8 x 2.9 x 1.8 m |

| Shipping Volume: | 3.5 m3 | 4.2 m3 | 5.7 m3 | 7.0 m3 | 9.0 m3 | 12.0 m3 | 15.0 m3 |

|

|

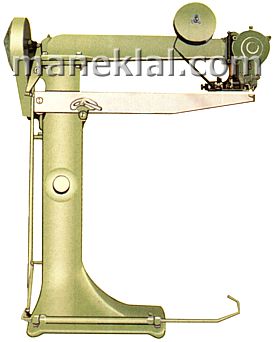

| Box Wire Stitching Machines - Angular Type |

|

|

Specifications: |

| Model: | BSM-20 | BSM-30 | BSM-36 | BSM-42 | BSM-48 | BSM-52 |

| Machine Size: | 20 / 50 cm | 30 / 76 cm | 36 / 91 cm | 42 / 106 cm | 48 / 122 cm | 52 / 132 cm |

| Speed (stitches/min): | 350 | 350 | 350 | 350 | 350 | 350 |

| Motor: | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP |

| Approx. Net / Gross Weight: | 225 / 300 kg. | 250 / 350 kg. | 275 / 375 kg. | 300 / 400 kg. | 350 / 450 kg. | 400 / 550 kg. |

| Shipping Volume: | 0.5 m3 | 0.6 m3 | 0.7 m3 | 0.8 m3 | 1.0 m3 | 1.1 m3 |

|

|

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |