|

|

| Paper Cone Making Machines |  |

Paper Tube Making Machines |

|

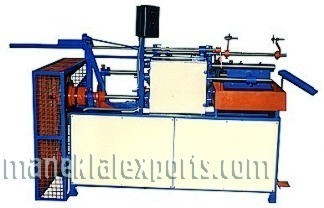

Pattern

Cutting Machine

A

heavy-duty clutch type machine, fitted with a pair of 10 length male

& female embossing rollers, paper roll shaft, paper roll shaft

adjustments, draw roller assembly carriage set with pattern cutting knife

suitable for 9.15. A blower collects the grinding dust. Supplied with 2 HP

motor for main drive and 1 HP motor for grinder drive with suitable

starters. |

|

Pattern

Cutting Machine A heavy-duty clutch type machine. This machine cuts 50 to 70 patterns at a time. Supplied with 7.5 HP motor and one die. |

|

|

Paper

Edge - Grinding Machine: For continuous edge grinding with conveyor system. Dust collected by a blower. Supplied with 1.5 HP motor with speed reducer gearbox and suitable starter. |

|

Semi

Automatic Paper Cone Winding Machine:

A

heavy-duty clutch type machine, which does all types of cone winding. It

has a glue tank with glue applying rollers for the patterns. All type of

cones can be manufactured on this machine simply by changing the cone

making spindle & press bar. Pattern feeding has to be done manually to

the spindle and ejection is by a pneumatic system. Machine supplied with

one type of spindle. Other types of spindles can be supplied at extra

cost. Supplied with 1.5 HP motor for main drive fitted with suitable

starter Production: 20 - 23 Cones / Minute |

|

|

Paper

Cone Cutting M

For

cutting the cone at top and bottom. Manual feeding to the spindle and

automatic ejection by stripper mechanism. Supplied with 1 HP motor for

main drive and suitable starter

|

|

Paper

Cone Nosing Machine:

For

cone nosing and bottom cutting. Feeding to the spindle is manual and

ejection is automatic by stripper mechanism. It is is fitted with 9.15

spindle. Other types of cone finishing spindles can be supplied at an

extra cost. Supplied with 1.5 HP motor for spindle drive and 1 HP motor

for main drive with suitable starter |

|

|

Printing

Machine:

For

printing at the top and bottom side of the cone. Cone loading to the

spindle is manual and ejection is by stripper mechanism. Suitable for

Water Colour Ink only. Supplied with one printing design, 0.5 HP motor and

suitable starter. Other types of designs can be supplied at an extra cost. Dimensions: 1.55 x 0.85 x 1.25 m |

|

Turret

Type Paper Cone Velveting Machine:

For

cone velveting of all types of cones and bottom side grooving.

Ejection of cone by stripper mechanism. The spindle can be changed quickly

and the velvet roller adjusted to any angle. Supplied with 5o 57

spindle, 1.5 HP motor for main drive, 1 HP motor for velveting drive and

suitable starters. Other types of spindle can be supplied at an extra

cost. Dimensions: 2.05 x 1.55 x 1.80 m |

|

Apart form the above machines, the following items are also required:

- Compressor with 2 HP motor and starter -

for Paper Cone Winding Machine - Cone Ejection

- 5o 57 attachment with carriage angle assembled with suitable 5o

57 knife change gear wheel, O.D. 5 x Bore 3 x Length 36 plain roller

- 2 Nos., winding spindle, nosing spindle, nosing cup and stripper plate

- Paper Cone Punching Machine Manually Operated:

- Punching moon shape at the bottom of cone

- Winding Spindles

- Nosing Spindles

- Velveting Spindles

|

Semi Automatic Paper Tube Making Machines - Capacity ID: 10 to 50 mm |

|

Semi

Automatic Parallel Paper Tube Winding Machine:

A

heavy-duty machine with clutch mechanism. Pattern feed by manual system.

Tube ejection by stripper mechanism. Application of paste automatic. This

machine can produce all types of tube of size minimum 10 mm to maximum 50

mm. Supplied with one type of spindle as required, 1.5 HP motor and

starter. Other types of spindles can be supplied at an extra cost. Dimensions: 1.8 x 1.3 x 1.6 m |

|

Tube

Cutting Machine: Dimensions: 1.3 x 0.7 x 1.0 m |

|

|

Paper

Edge - Grinding Machine: For continuous edge grinding with conveyor system. Dust collected by a blower. Supplied with 1.5 HP motor with speed reducer gearbox and suitable starter. Dimensions: 1.3 x 1.0 x 1.5 m |

|

Semi Automatic Paper Tube Making Machines - Capacity ID: 50 to 125 mm |

|

Spiral Tube winding machine: Used for 16+1 winding and to produce tubes of I.D. 50 to 125mm. Size of the tube can be changed quickly. Supplied with 7.5 HP variable speed DC motor, reducer gearbox, panel board, reel stand, water pump (0.5 HP) heater, blower and one mandrel of required size. Other size mandrels available at extra cost. Production speed: can be varied from 5 to 15 feet per minute. |

|

Auto

Paper Rough Cutter Machine:

Used for cutting rough size of any length. Supplied with a circular saw blade, 2 HP motor, solenoid valve & dust collecting blower with starter. |

|

|

Paper

Tube Trim Cutting Machine:

This machine has 6 circular knives and is supplied with 1 HP motor & starter. By adjusting this machine, any length of tube can cut (mandrel size maximum length 40") |

|

Gluing

Tank:

For continuously applying glue on 16+1 layer papers through pipes and suitable guides. Supplied with 2 HP motor, gear pump, 6 kW heater & starter. |

|

|

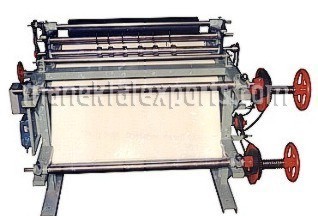

Paper

Slitting Machine:

This machine has a high speed 36" reel paper slitting and rewinding system of any width and rotary knife holder with knives of 12 set (top & bottom). Supplied with a 3 HP motor & starter. |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |