|

|

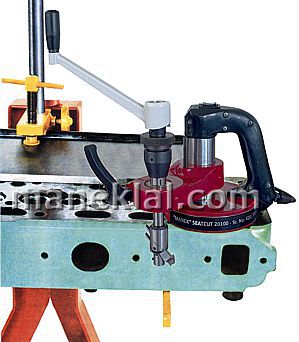

| Motorized Valve Seat Cutting Machine Model: VSC-3M & VSC-6M | Valve Seat Cutting Machines Model: Seatcut-20100 & VSC-B |

| Motorized Valve Seat Cutting Machine Model: VSC-3M & VSC-6M |

|

|

| Specifications: |

| Model: | VSC-3M | VSC-6M |

| Spindle (mm): | 60 | 65 |

| Max. Spindle Travel (mm): | 130 | 150 |

| Max. Spindle Tilt: | 20o | 30o |

| Distance from Table to Spindle (mm): | 310 | 410 |

| Min. Seat Cutting Diameter (mm): | 14 | 14 |

| Max. Seat Cutting Diameter (mm): | 40 | 60 |

| Spindle Speed (variable): | 25 - 200 rpm | 50 - 300 rpm |

| Spindle Head Travel (front & back) (mm): | 40 | 60 |

| Spindle Head Travel (left & right) (mm): | 700 | 850 |

| Clamping Block Travel (front & back) (mm): | 130 | 150 |

| Clamping Table Size (mm): | 500 x 1000 | 600 x 1100 |

| Spindle Motor: | 1 HP | 1 HP |

| Air Requirement: | 100 psi 4 bar | 100 psi 6 bar |

| Net / Gross Weight (kgs.): | 650 / 1050 | 700 / 1100 |

| Dimensions (m): | 1.25 x 1.00 x 2.20 | 1.45 x 1.15 x 2.35 |

| Shipping Volume (m3): | 3.0 | 4.0 |

|

Standard Accessories: With VSC-3M: Air Gun Set, Digital Centering System, Single Cylinder Clamping Plate, 5 nos. Steel Guide Stems, 2 nos. Cutting Tools (45o), Ball Head (cutting holder) of 0.236” / 6 mm, Tip Holder (14 to 25 mm), 6 nos. Stainless Steel Springs, 4 nos. Brass Bushes, Tilting and Lifting Mechanism for Cylinder Heads, 2 nos. Job Support Plate, Cutter Blade Removal Screw Driver, Allen Key Set, Spanner, 4 nos. Leveling Bolts With VSC-6M: Air Gun Set, Digital Centering System, 10 nos. Steel Guide Stems, 2 nos. Cutting Tools (45o), 1 no. Cutting Tool (30o), 1 no. Chamfering Tool (45o), 1 no. Phasing Tools (90o), Ball Head (cutting holder) of 0.236” / 6 mm, Ball Head (cutting holder) of 0.375” / 9.5 mm, Tip Holder (14 to 25 mm), Tip Holder (24 to 40 mm), Tip Holder (40 to 60 mm), 6 nos. Stainless Steel Springs, 6 nos. Brass Bushes, Tilting and Lifting Mechanism for Cylinder Heads, 2 nos. Job Support Plate, Cutter Blade Removal Screw Driver, Allen Key Set, Spanner, 4 nos. Leveling Bolts Optional Accessories: Vacuum Tester Set, Depth Measuring Set, Tool Grinder, Lapping Unit, Additional Tip Holders in different sizes, Inserts, Reamers, Drills, Guide Stems in Steel or Carbide, Pilots, etc. |

|

|

| Valve Seat Cutting Machines Model: Seatcut-20100 & VSC-B |

Model: Seatcut-20100 |

Features: |

|

Specifications:

|

|

|

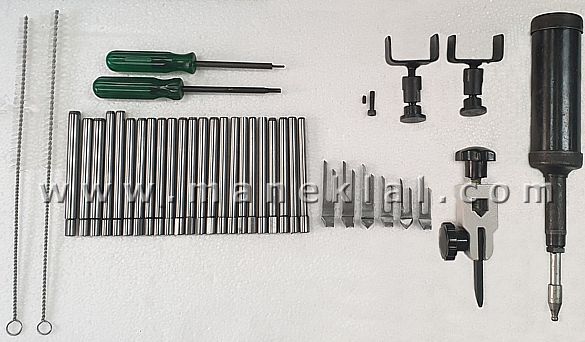

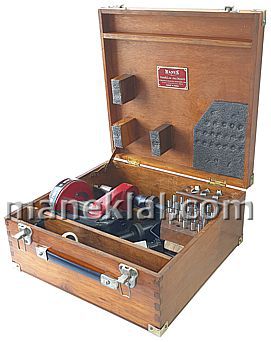

Standard Accessories: Basic machine, power control unit, operating tools, carrying case, formtools and pilots (detailed hereunder), Wall Mounting Bracket with special mounting bolts (suitable for fixing all types of cylinder heads). (For model VSC-B, instead of the Wall Mounting Bracket, a Bench and motor drive are provided, as shown in the picture) Formtools, Small (24 - 34 mm diameter): 1 piece 15o x 45o x 75o - 1.5 mm seat width, 1 piece 0o x 30o x 60o - 1.5 mm seat width, 1 piece Counter Boring Tool Formtools, Large (34 - 44 mm diameter): 1 piece 15o x 45o x 75o - 1.5 mm seat width, 1 piece 0o x 30o x 60o - 1.5 mm seat width, 1 piece Counter Boring Tool Pilots (23 Pieces): 6.980, 6.995, 7.930, 7.952, 7.980, 7.995, 8.002, 8.020, 8.500, 8.520, 8.641, 8.672, 8.685, 8.692, 8.705, 8.709, 8.718, 8.725, 8.980, 9.000, 9.980, 11.086 and 11.105 mm

|

Wall Mounting Bracket |

Seatcut-20100 in Carrying Case |

Seatcut-20100 in Carrying Case |

|

|

|

|

|

Operation Sequence for Valve Seat Cutting Machines |

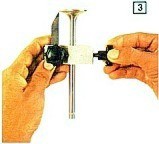

Fastening of the Pilot Select a Pilot that fits snugly into the valve guide. Tighten the grub screw to hold the pilot in place. (Please note that a snug fit is essential for a perfect finish on the valve seat) |

Mounting of the Formtool Select the Formtool as per the engine manufacturer’s specifications and insert it into the tool slot

|

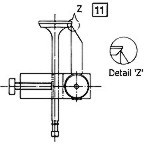

Gauging for Valve Connect Area Insert the valve stem into the formtool setting gauge as shown and slightly tighten the lock screw, permitting the gauge to be movable. Bring the tip of the pointer into contact with the valve face and lock it at the outer diameter of the desired future seating area (Refer fig. 11 below) |

Transferring the Valve Diameter to the Formtool Insert Formtool setting gauge over the pilot and tighten it so that it is still movable. Loosen the Formtool lock screw and let the Formtool tough the tip of the gauge pointer just at the meeting point between the seat angle and the external correction angle. This meeting point would be the outer diameter of the desired future seating area (Refer fig. 12 below) |

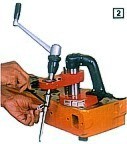

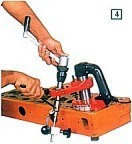

Positioning the Unit The Pilot is now introduced into the clean guide. Hold and guide the unit with both hands as shown in the figure. Place the magnetic base on the cylinder head / steel plate, suitably maneuvering it. Adjust the pre-setting screw so that the tool does not tough the seat. Centre the unit by turning the drive handle 2 or 3 turns. |

Locking After centering, energize the electromagnet by putting the switch to position 1 and lock the swiveling arm. Repeat this 2 to 3 times to ensure proper alignment. A uniform load will be felt on the handle if the centering is correct.

|

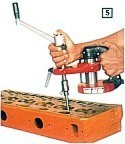

Seat Cutting Operation Having set the machine, turn the drive handle clockwise as regularly as possible, operating the advancing device as required. (Never turn the handle in the anti-clockwise direction when the Formtool is under pressure as this would damage the carbide tip) In case of very tough chromium seats, rub the seats with an abrasive cloth and use a suitable lubricant - gasoline or kerosene - during cutting operation |

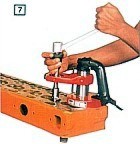

Removal of the Unit When the seat is ready, retract the tool by a few turns of the advancing device. Demagnetize the base by pressing the switch to position 2 for a moment. The unit may now be transferred to a similar seat without any further adjustment. Note: Only one tool setting is necessary per seat diameter Lubrication: If the unit is in continuous service, it may be oiled daily at the 2 oil nipples located in the swiveling arm and the knurled nut. |

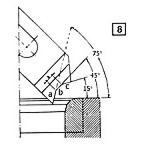

Tool Geometry |

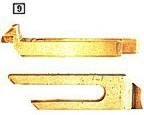

Formtools |

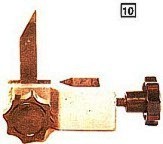

Formtool Setting Gauge |

Seat Gauging |

Dimension Transfer |

|

Maneklal Global Exports |

|

TO OUR PAGE ON AUTOMOTIVE ENGINE REBUILDING MACHINES |